STILLNESS at the touch of a button

Precision fertilisation with WindControl

Wherever you are in the world, the wind is always blowing. According to Prof. Dr. Karl Wild, of HTW Dresden, the influence of wind on the spread pattern can be continuously monitored and automatically compensated for by a wind sensor. This enables an optimum spread pattern to be generated, even in difficult windy conditions.

The challenge: the wind is always blowing

Sometimes stronger, sometimes weaker, sometimes continuously, sometimes gusting and from all different directions. As a result, spreading fertiliser within a tramline can be subject to different wind speeds and changing wind directions. When spreading fertiliser, wind is a parameter that you, as the user, can never influence directly. In practice, you spread your fertiliser on calm days, but even then, the wind continues to have a direct influence on the accuracy of application. In a cross wind, the spread pattern is compressed on one side and stretched on the other, creating an asymmetrical pattern. The aim of WindControl is to adapt the settings of the fertiliser spreader in real time, to maintain a symmetrical and precise spread pattern.

The solution: WindControl

A high-frequency wind sensor attached to the machine measures both the wind speed and direction and conveys this information back to the job computer. Using this data, the computer calculates new settings for the delivery system and spreading disc speed, which are then automatically adjusted. In a cross wind, the disc speed is increased on the side into the wind and the delivery system is rotated outwards. At the same time, the disc speed is decreased on the side facing away from the wind and the delivery system is turned inwards. This automatically counteracts the effect of the wind, to ensure optimal lateral distribution. With WindContol, the spreading accuracy remains at a very high level, even under the influence of wind. In addition, WindControl creates larger time frames for spreading in windy conditions. As well as all the important parameters, you always have an eye on the current wind parameters, such as direction, speed and gustiness. WindControl also issues an automatic warning in strong winds, when the system is no longer able to compensate for the effects of the wind or when there are too many gusts of wind from different directions.

The wind sensor is automatically extended or retracted when the spreading discs are switched on or off. When extended, the wind sensor protrudes above tractor to prevent any air turbulence caused by the tractor being measured. When retracted, the wind sensor is located between the tractor and the spreader to protect it from low-hanging branches during road travel.

WindControl in practice: The economic efficiency

Key data and information

- Field size 70 ha

- Wind speeds of up to 27 km/h

- WindControl improves the lateral distribution across 70 % of the area*

- This means an additional yield of 24 €/ha as a result of WindControl*

* Results based on long-term trials

Example farm:

- Size of farm: 500 ha

- Average wheat yield: 7.8 t/ha

- Average profit: 280 €/t

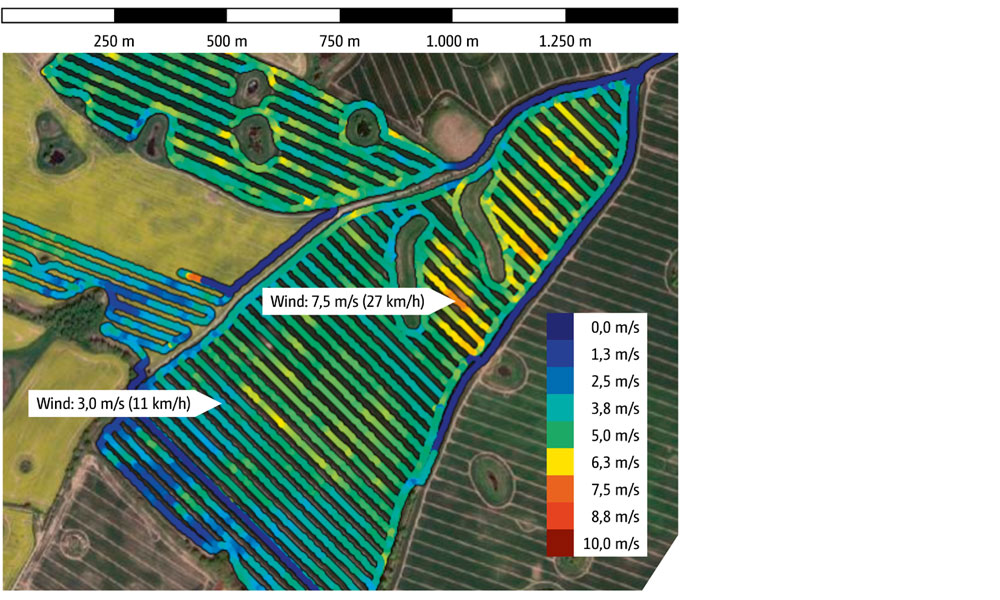

The wind is always blowing during the spreading season. Wind speeds of up to 27 km/h were measured on the 70 ha field during spreading. An average wind speed of 14 km/h was recorded. WindControl compensated for the effect of the wind on 70 % of the area during spreading, thereby optimising the lateral distribution by 5.6 %. Only 30 % did not require optimisation. This results in improved nutrient distribution and more uniform crops.

Based on long-term trials, which investigated the relationship between fertiliser distribution and the effect on yields, this provides an additional yield of ~1.1 % (Δ CV 5% = 1 % increase in yield). This corresponds to an additional revenue of 24 €/ha as a result of WindControl.

NEW Now available separately from the ArgusTwin

WindControl

- Higher output through longer windows of use

- Increased yield through optimised lateral distribution

- Operational safety via the automatic warning system

WindControl traffic light system

- Green: Unlimited spreading

- Yellow: Increased control in border areas

- Red: Stop spreading!

ArgusTwin

Permanent monitoring and optimisation of the lateral distribution for each spreading disc via a total of 14 radar sensors. The effect of fluctuating fertiliser properties and qualities, changes in humidity and differing ground topography is automatically compensated for and a spread pattern with perfect lateral distribution maintained.

Profis weighing system

Precise monitoring and control of the application rate via the 200 Hz weighing technology and the tilt sensor. Input the spread rate, drive off and always apply the right quantity, even when border spreading and in wedge-shaped fields and, at the same time, have perfect control over the hopper fill level.

NEW: ProfisPro weighing system with FlowControl

ProfisPro combines the advantages of the weighing system with the FlowControl torque monitoring system: In addition to weighing, the quantity to each side is controlled by measuring the torque on each spreading disc. This guarantees a precise application rate from the very first second. Moreover, the ProfisPro spreader is equipped with independent high-speed monitoring and control of the two outlet openings.

AutoTS disc-integrated border spreading system

AutoTS guarantees the user significantly higher yields in the border area in comparison with existing border spreading procedures. You can conveniently switch between normal spreading and border spreading from the cab while driving, and activate side, border or water course spreading at any time, according to the headland location. Amazone offers settings for all these techniques.

GPS-Switch and DynamicSpread automatic part-width section control

Thanks to different spreading disc speeds, the hydraulic system enables the use of WindControl and ensures optimal lateral distribution during side, border and water course spreading. The automatic part-width section control with up to 128 part-width sections in the form of a kidney-shaped pattern guarantees a highly-precise shut-off in wedge-shaped fields or on the headland. Outer part-width sections can also be controlled.

NEW: HeadlandControl

- Widening of the headland for optimisation of the on/off switching points

- Optimum lateral distribution through optimised overlap zones on the headland

AmaTron 4 operator terminal

With the new AmaTron 4 ISOBUS terminal and its 8" multi-touch colour display, AMAZONE has developed an ISOBUS terminal where comfortable fertilisation is a matter of course. 12 switch buttons on the touch display and another 12 soft keys allow intuitive operation in both day and night mode.

- GPS-Switch: automatic part-width section control with up to 128 part-width sections, including marking of obstructions

- GPS-Maps&Doc: documentation and the processing of application maps is easy and precise

- Use of on-line N-sensor technology for part-area, site-specific fertilisation enabling needs-based plant nutrition

AmaTron Twin screen extension

New App for a more comfortable display of the field view by integrating your own tablet.