New ploughs - 100 % AMAZONE technology

The new Teres and Tyrok ploughs with 100 % AMAZONE DNA

Maximum robustness and outstanding quality of work

The plough as the initial plant protection measure

It is not just the philosophy but the right choice of soil tillage method that is critical to success. On many farms, both conventional sowing and mulch sowing methods are practised in combination, depending on the weather. The yield-guaranteeing function of the plough is the decisive factor here.

In practice, the system offers the following advantages:

- Effective weed control via mechanical means by light deprivation and reliable control around field borders

- Quicker soil warming and better soil aeration for increased yields in crops demanding higher soil temperatures

- The only soil tillage option in constantly wet conditions

- Reduced risk of disease carryover to the following crop

- Accelerates the microbial activity in the soil by oxygen enrichment

- Mechanical control of slugs and UV-light sensitive soil pests

AMAZONE know-how brings the highest quality

New AMAZONE top-class reversible ploughs

AMAZONE offers unique advantages for your farm with the Teres mounted and the Tyrok semi-mounted reversible ploughs – 100% of the technology comes from AMAZONE. AMAZONE ploughs are characterised by their robust build strength, an excellent quality of work, optimal adaptation to local conditions and thus offer the highest possible cost-effectiveness.

An excellent example is AutoAdapt, which automatically adjusts the front furrow when the overall furrow width is changed. Precise matchup of the furrows is possible under any conditions thanks to the parallelogram linkage and the hydraulic connection between the furrow width and front furrow cylinder. The accurate matching to the last furrow ensures perfect work results. AutoAdapt also has a positive effect on fuel consumption, since the pull point is not changed during the process.

See for yourself!

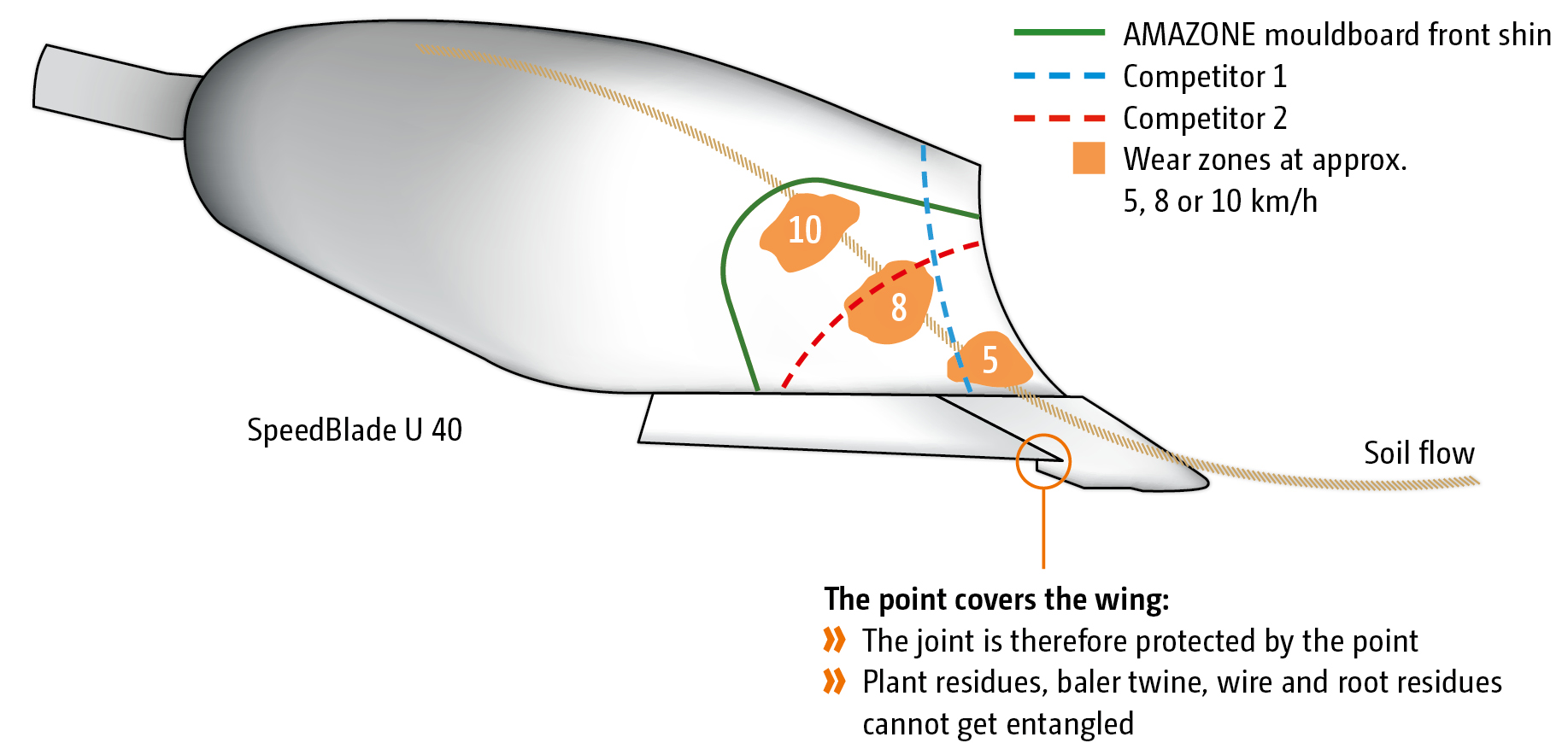

Unique –AMAZONE SpeedBlade

The new innovative plough body

The new innovative SpeedBlade plough bodies, with their patented extra-large front shin on the mouldboard and the ©plus hardening process, ensure significantly less wear at higher forward speeds. As ploughing speeds increase, the wear point shifts further backwards. Wear on conventional plough bodies begins directly on the mouldboard at higher speeds as a result of the small front shin of the mouldboard. With AMAZONE, only the front shin of the mouldboard has to be replaced thanks to the patented enlarged front shin. This avoids the troublesome and expensive replacement of the entire mouldboard.

Teres 300 mounted reversible plough

The plough for all situations

Work without compromise

AMAZONE offers the right solution for any farm with the Teres mounted reversible plough. The plough is characterised by its simple adjustment, extremely low pulling power requirement and a perfect working profile.

The benefits:

- The AutoAdapt hydraulic front furrow adjustment is fitted as standard and generates the perfect matching to the last furrow, even under changeable conditions

- Wide furrow clearance by the state-of-the-art plough body concept

- Simple adaption of the front furrow thanks to the infinitely-variable hydraulic adjustment

- Rapid and gentle turnover process at the larger furrow widths as a result of the SmartTurn frame swivel cylinder

- Wide choice of various side-mounted and rear-mounted support wheels for good transport on the road and reliable and tidy working in the field

- ProtectShaft cross-shaft with integrated bearings for damping shock loads on the headland

- Unique SpeedBlade plough bodies with an enlarged front shin of the mouldboard and the ©plus hardening process means higher speeds with less wear for the Tyrok and Teres

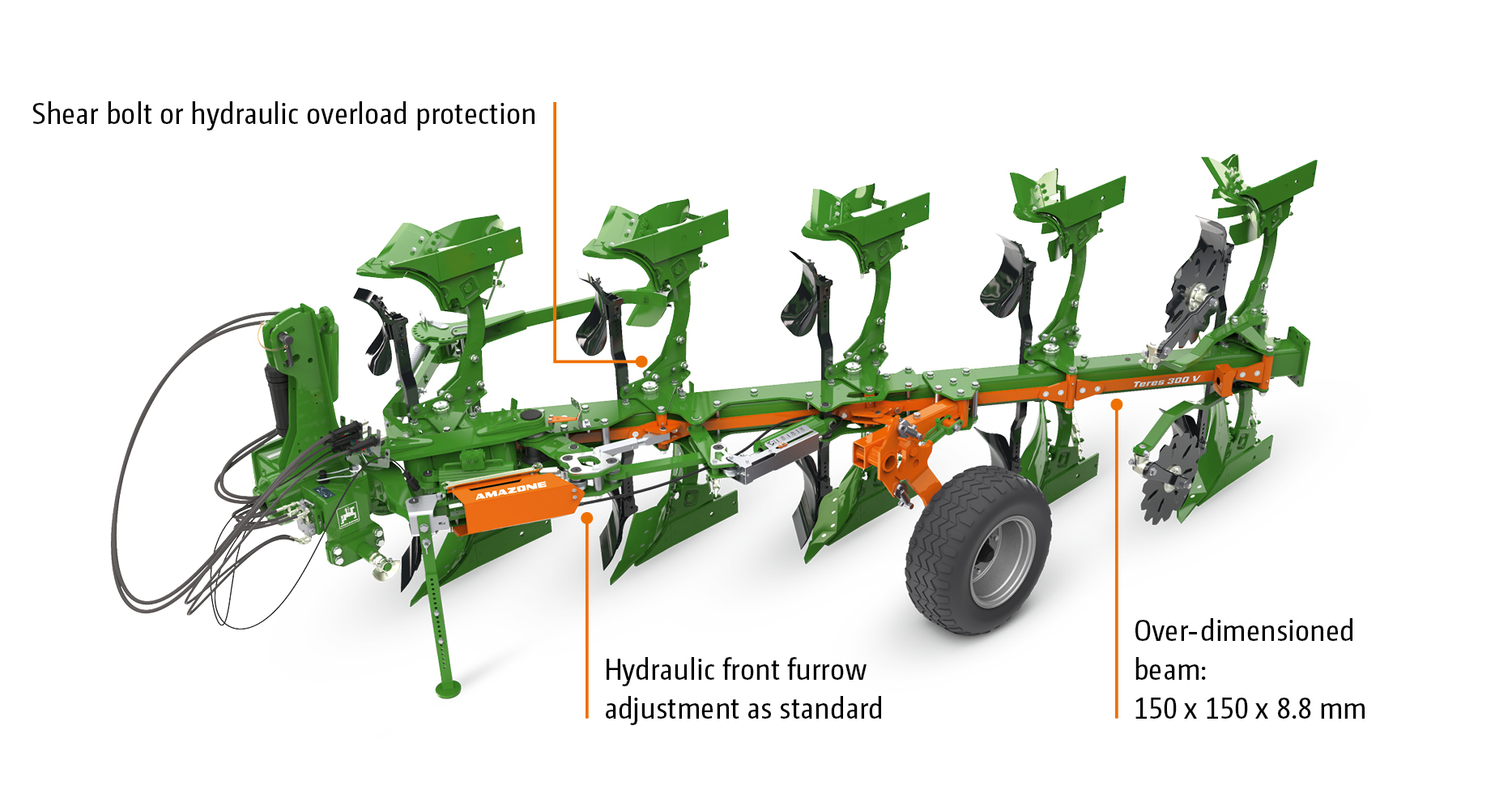

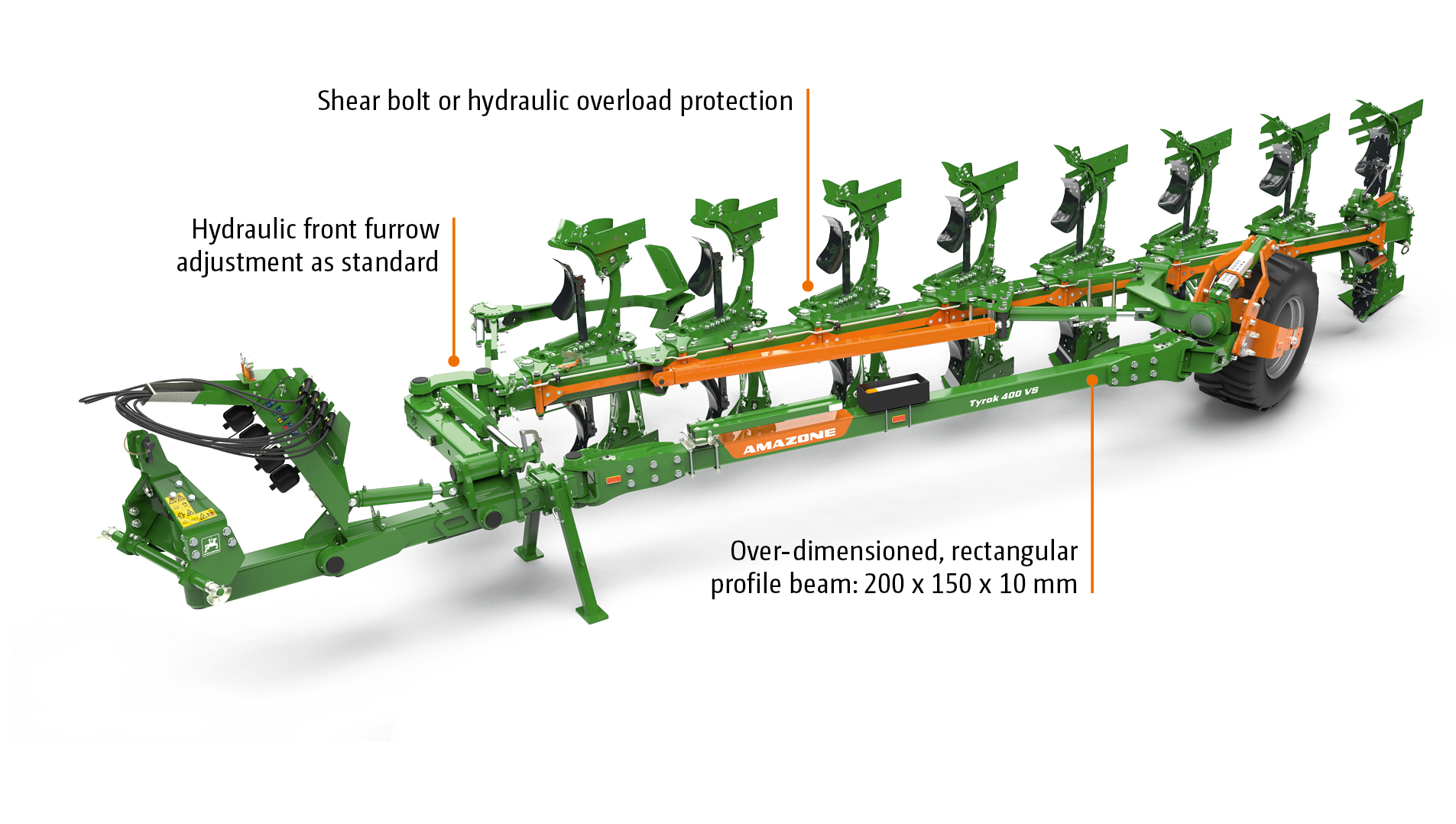

Tyrok 400 semi-mounted reversible plough

Meticulously designed from top to bottom

From medium-deep to intensive

AMAZONE offers unique advantages for your farm with the highly efficient and extremely robust Tyrok semi-mounted reversible plough. The SmartTurn two-stage hydraulic end position damping enables the turnover process to be quickly carried out with minimal material stress. At the same time, the new over-dimensioned rectangular profile beam ensures a constant furrow depth over the full furrow width.

The benefits:

- Perfect matching to the last furrow, even under varying conditions, thanks to the direct linkage of the front furrow cylinder

- Wide furrow clearance by the state-of-the-art plough body concept

- Rotation of the headstock by 180° to improve the pull line

- Unique SpeedBlade plough bodies with an enlarged front shin of the mouldboard and the ©plus hardening process allow higher speed with less wear in the Tyrok and Teres

- AutoAdapt – automatic, precise adjustment of the front furrow width when changing the furrow width

NEW: Now also available as an OnLand version for tractors with wide tyres or on tracks

- Soil-conserving, tractor-independent and fuel-efficient as a result of an optimum pull line, especially with a large number of furrows

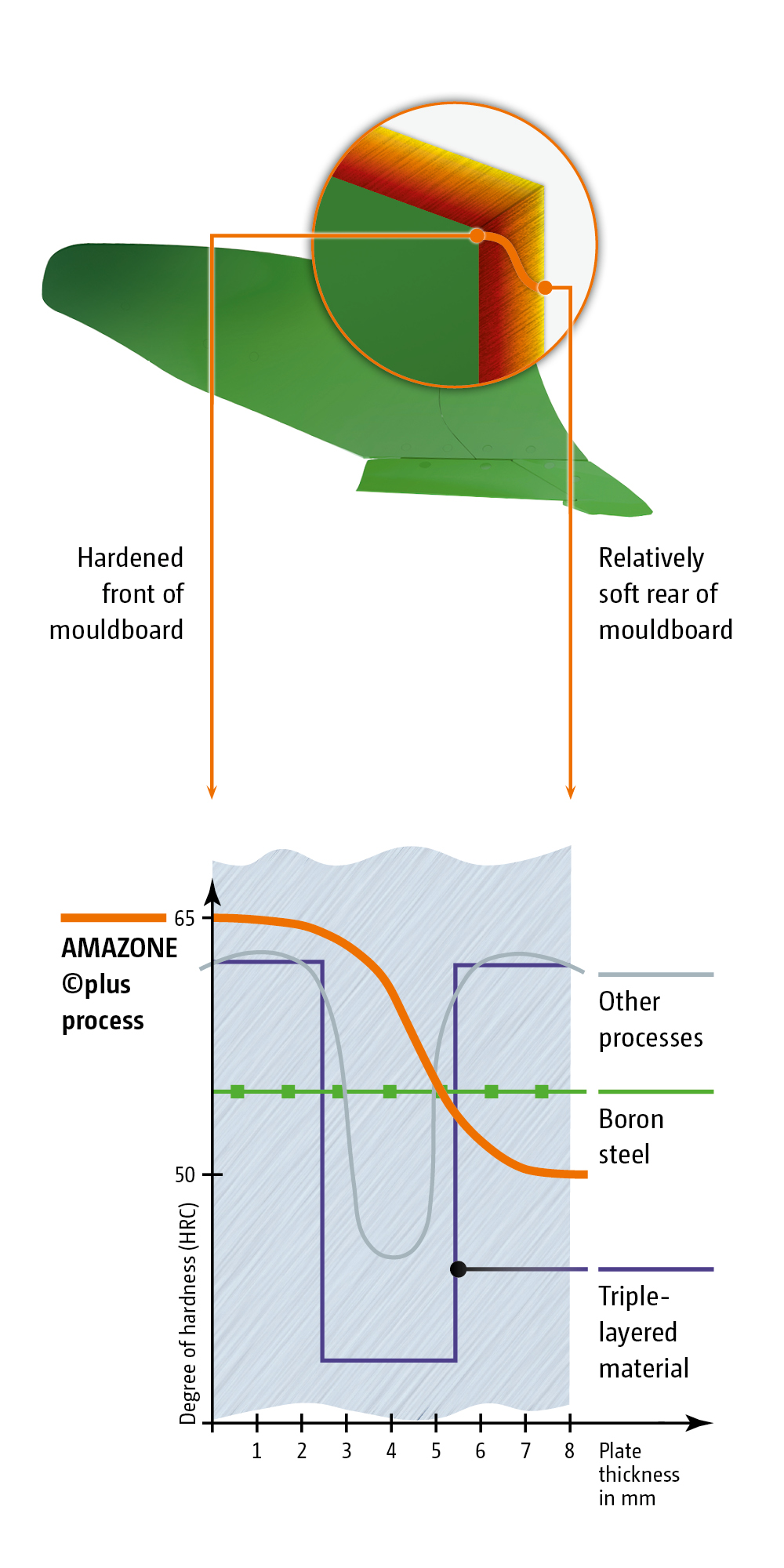

First-class quality for long-lasting wear parts

The AMAZONE ©plus hardening process – the know-how of heat treatment

Our heat treatment know-how is the basis for the highest possible quality in our wearing parts for ploughs. Carbon in its purest form, diamond, is the hardest naturally occurring substance. A hardening process which involves introducing carbon into the steel is used to increase the hardness and durability of ©plus wearing parts. AMAZONE uses a unique hardening process to achieve a very high level of hardness on the front of components, such as the shin, to produce the optimum resistance to wear. The back remains relatively soft but at the same time extremely tough and impact resistant.

Benefits of the ©plus hardening process:

- Longer service life

- High impact resistance

- Less pulling power requirement

- Reduced fuel consumption

- Less sticking to the smoother outer surface

AMAZONE plough bodies

Reliable – Easy to pull – Fuel-efficient