12 Sep 2023

FertiSpot for the Precea precision air seeder

Spot-accurate fertiliser application:

Now also synchronised between the seeds and for all Precea models

The FertiSpot system ensures spot-accurate application of the fertiliser under the seed. Owing to the legal requirements for a reduction in the permitted amount of fertiliser used, the challenge lies in using fertiliser more and more efficiently. This has compelled AMAZONE to further develop the FertiSpot system. AMAZONE will be showing FertiSpot at Agritechnica 2023 with the additional option of synchronised fertiliser placement between the seeds.

AMAZONE introduced the FertiSpot system in 2019 with placement of the fertiliser under the plant. The system uses the fertiliser as efficiently as possible, especially in maize sowing. As a result of the increase in the use of precision sowing for other crops, AMAZONE has further developed the FertiSpot system. The new development provides synchronised placement of the fertiliser portions between the seeds with the result that the system enables high concentrations of fertiliser while protecting sensitive crops from burning. In particular, this offers advantages in other crops such as sugar beet. Application between the seeds benefits all crops, especially in very dry soil conditions. If the fertiliser is placed too close to the seeds, it will deprive the plants of the necessary moisture, meaning that the seeds could dry out or have an insufficient supply of water.

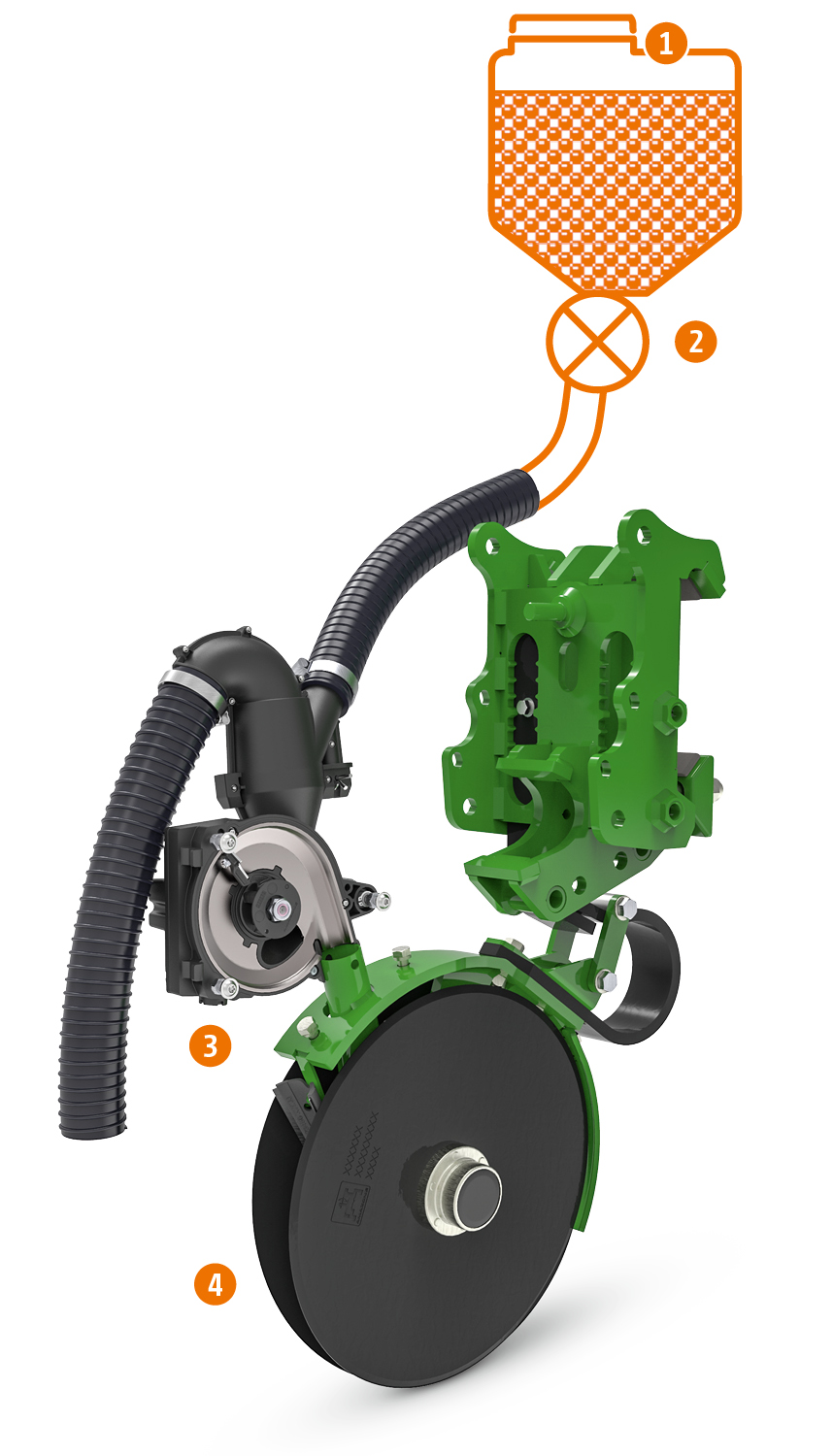

Structure of FertiSpot with granular fertiliser

The Precea precision air seeder with FertiSpot for granular fertiliser placement has a fertiliser hopper with fertiliser metering just like the traditional precision air seeder. The metering regulates the desired application rate per hectare. This can be varied using application maps. In conjunction with individual row shut-off, the fertiliser can be switched off across each row in wedge-shaped fields and tapering headlands via Section Control.

The mineral fertiliser is transferred from the fertiliser metering system to the FertiSpot fertiliser portioning unit. The fertiliser flow, which continuously enters the portioning unit, is combined by a high-speed portioning rotor. It leaves the unit as a portion and is delivered to the fertiliser coulter. The control of the portioning unit and delivery of the seed are synchronised. Control is provided via the Precea ISOBUS control system. The further development of FertiSpot means that the fertiliser can now be delivered both as a portion directly under the plant and as a portion between the seeds. The tractor driver can enter the precise location of the spot via the ISOBUS control system. The fertiliser depot can be offset with the enhanced FertiSpot metering. The tractor driver can enter the precise location of the spot under the seed or as a possible offset between two seeds via the ISOBUS control system. Furthermore, band application is also possible with FertiSpot. The special design allows application rates of up to 250 kg of fertiliser per hectare depending on the machine specification and irrespective of the fertiliser type.

Better utilisation of the fertiliser by the plant

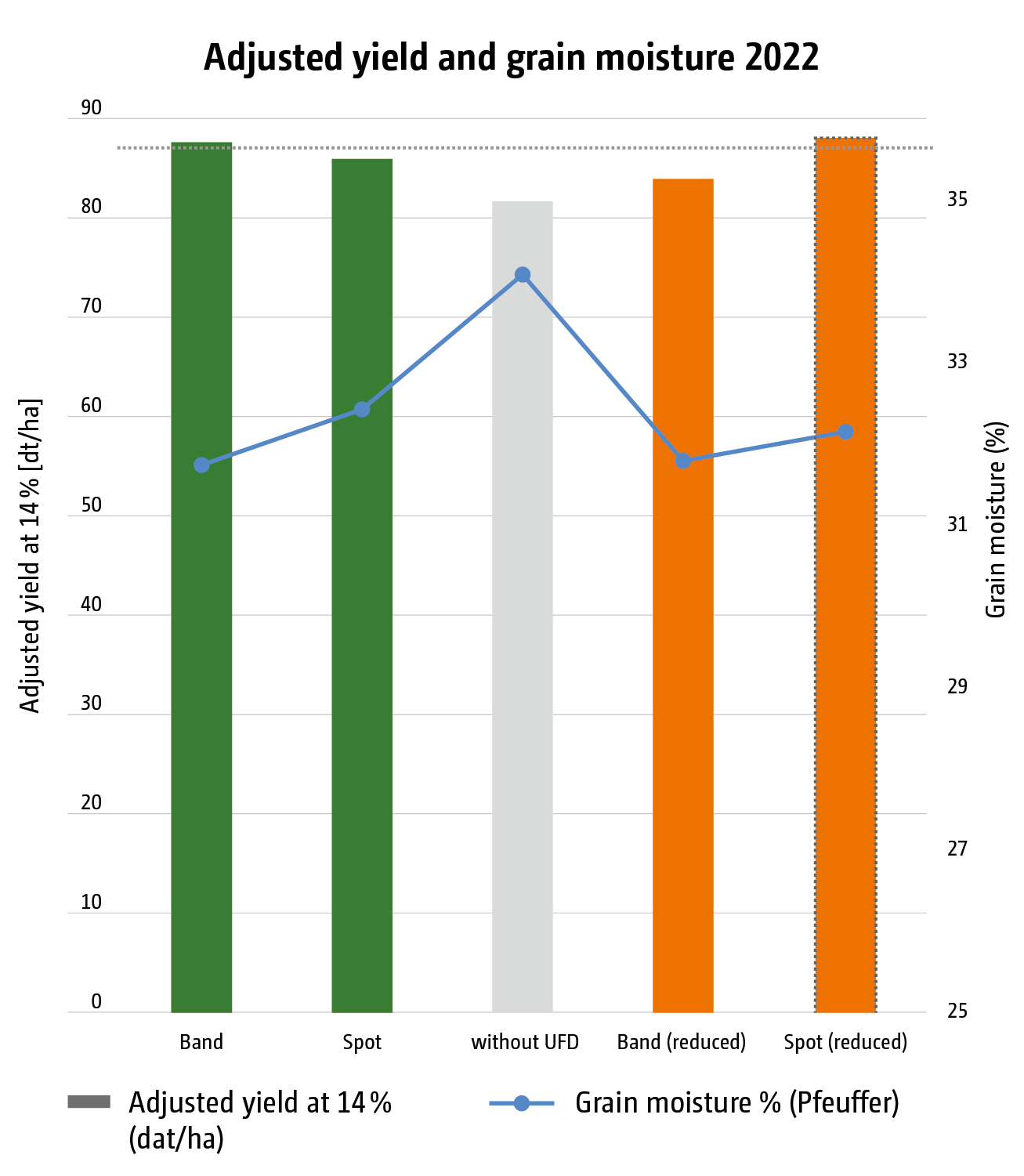

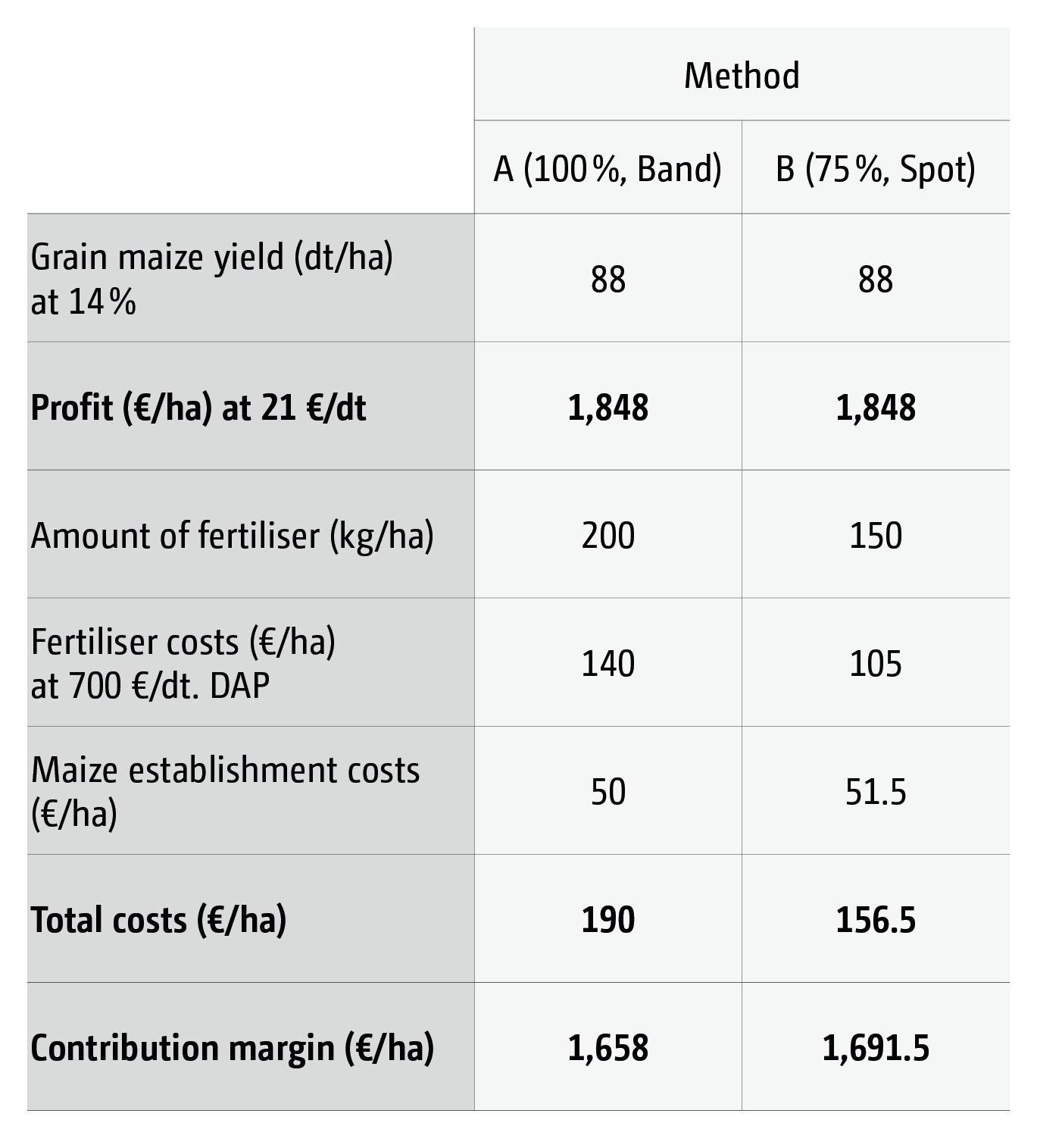

Targeted placement of the fertiliser in the area of the seed leads to clearly improved nutrient utilisation, since the availability to the plant increases. The higher availability provided by spot application allows for a reduction in the total amount of fertiliser applied per hectare. Investigations carried out by the Technical University of Cologne predict fertiliser savings of 25% with the same yield level.

In addition to the positive effects on environmental protection, there are further advantages for operational and work management. Direct cost savings from the reduced amounts of fertiliser required per hectare are accompanied by additional savings due to the higher work rates while sowing, since refill stops are reduced by 25 %. In regions with a large animal stock levels, mineral fertiliser can be saved and the farm manure can be put to more effective use.

The high saving in fertiliser not only provides considerable added value for the farmer, but contractors also save time and money, since they can increase output as a result of the reduced amount of downtime for fertiliser filling. The environment also benefits from the reduced and more efficient use of fertiliser.

The further development of the FertiSpot system enables it to be used in various crops. The variable application between the seeds means that the fertiliser can also be placed as a deposit for sensitive crops. Crops which are sensitive to fertiliser, such as rape or sugar beet, can therefore be optimally supplied with a reduced amount of fertiliser.

- FertiSpot allows the amount of fertiliser to be significantly reduced and the environment is protected

- Benefits of the reduced amount of fertiliser:

- Farmer: lower fertiliser costs

- Contractor: higher output due to shorter turn-round times

FertiSpot for the Precea precision air seeder