18 Nov 2022

Tyrok 400 semi-mounted reversible plough

New flagship in the plough range – higher speed for higher output with minimum wear

With the Tyrok 400, AMAZONE now launches a completely new semi-mounted reversible plough in a choice of seven, eight, or nine furrows for the 400 HP tractor class. The main features of this plough are its higher output, even under continuous load, perfect quality of work and outstanding robustness. At the same time, the Tyrok offers a high level of comfort thanks to its very simple, reliable and exact adjustability.

Plough bodies meticulously thought-through – SpeedBlade for improved performance

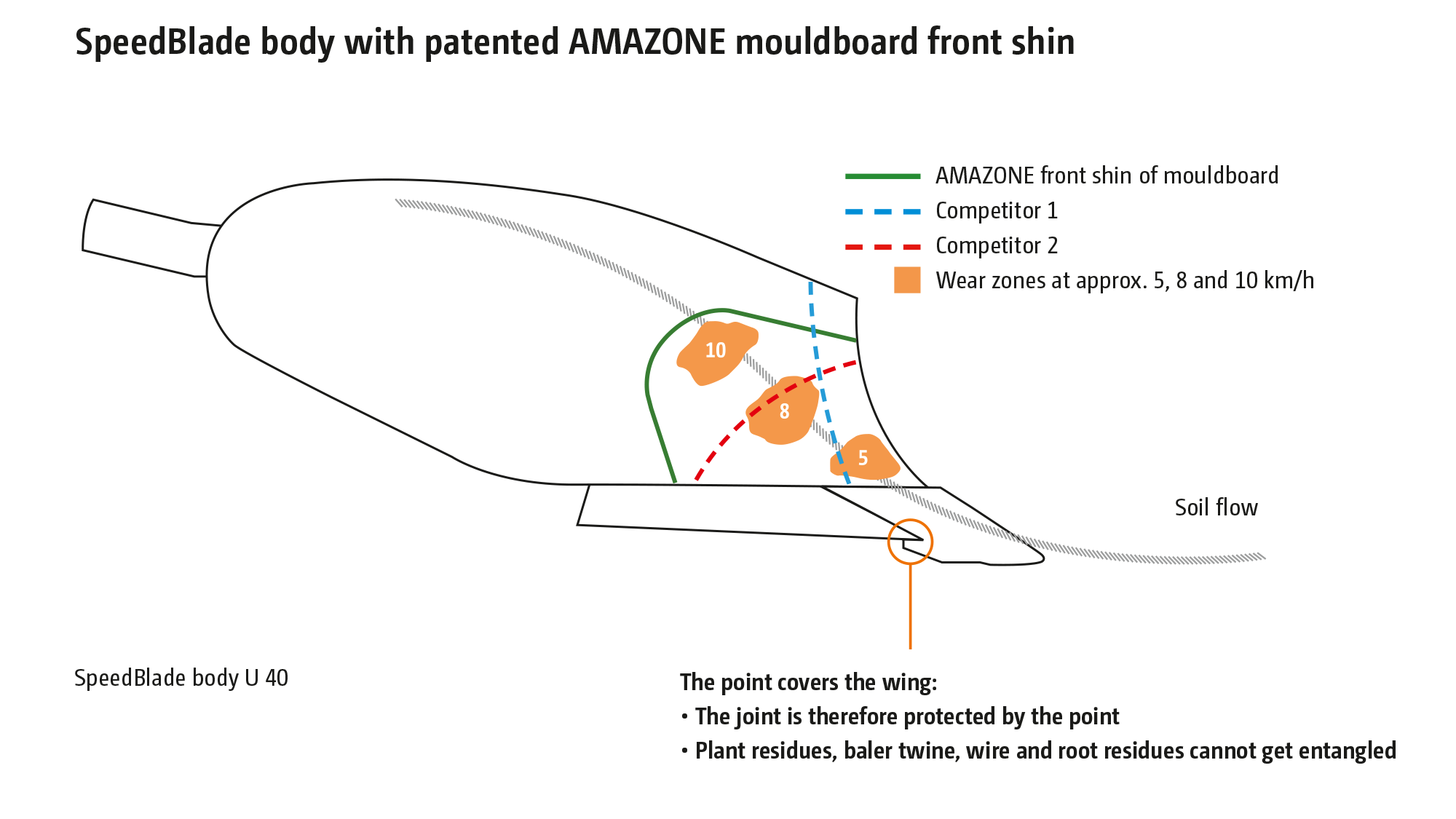

The new SpeedBlade plough body, with its patented extra-large front shin on the mouldboard, makes for minimal wear on the main mouldboard. The main wear point automatically shifts further and further back towards the centre of the plough body as the working speed increases from say 6 km/h up to 10 km/h. As a result, the main wear point of the SpeedBlade plough body is kept on the enlarged front shin of the mouldboard and not back on the main part of the slatted or solid mouldboard, even at these higher forward speeds, meaning, therefore, that only the front shin of the mouldboard needs to be replaced initially on the Tyrok when used at higher speeds. This enormously reduces wearing costs compared to other designs.

Another detail with great effect: the point covers the wing, meaning that the joint is protected by the point. Thanks to this clever join up, no plant residues or baler twine can get entangled. In addition, the open frog prevents soil from sticking under the frog due to its profile so that the maximum ease of pull on the plough body is maintained.

The unique ©plus hardening process provides the basis for high quality during the manufacture of Tyrok wear parts and is a result of the additional introduction of carbon. For example, a very high hardness and thereby a smooth surface is achieved on the front of the mouldboard which ensures a long service life for the wear parts. The reverse side remains, however, relatively soft and is therefore extremely tough and impact resistant.

The SpeedBlade plough body range offers a selection of different slatted and solid mouldboard profiles, depending on the application and the objective. The sophisticated design of the plough bodies combined with the advantages of the ©plus hardening process ensure a low pulling power requirement, thereby reducing fuel consumption. As an option for use in particularly tough conditions, HD share points can be ordered for shorter downtimes and less wear.

The wide furrow clearance is another big plus of the SpeedBlade bodies, especially with the increasing use of wider tractor tyres.

Pure robustness without compromises

The Tyrok is particularly robust thanks to the strong, high-tensile steel rectangular tubular beam having dimensions of 200 x 150 x 10 mm. A decisive benefit over beams from other manufacturers is: the beam does not bend during work even under high loads. This ensures a uniform working depth over the entire length and working width.

The Tyrok also scores points with its new SmartTurn turning system. At the headland, the fast turning procedure is hydraulically slowed down twice just before the end. This results in a damping effect which reduces stress on the plough structure when the cylinder is retracted. There is no need to compromise on speed as the low-stress turnover process is completed within a period of just nine seconds.

The optionally available hydraulic overload safety protection also ensures smooth and material-protective working in arduous operating conditions. The plough body is gently pushed back into the soil via the hydraulic cylinder. The trigger force decreases as the lift height increases. Trip forces of up to 2000 kg can be infinitely adjusted either centrally or separately on each individual body, depending on the operating conditions.

Safe, comfortable and precise adjustment for a perfect working profile

The Tyrok is equipped with mechanical furrow width adjustment as standard. As an option, the working width can be infinitely adjusted hydraulically to suit the conditions from the comfort of the tractor cab. The new AutoAdapt automatic front furrow adjustment offers a huge advantage in terms of comfort and precision. The hydraulic adjustment of the overall working width automatically adapts the front furrow precisely to the changed working width using the intelligent kinematics of the Tyrok. The basic adjustment of the front furrow or possible adaption is carried out hydraulically from the cab. As a result, changing soil conditions or slopes can be responded to consistently and quickly, thereby enabling perfect matching to the last furrow.

The working depth is mechanically or hydraulically adjusted via the standard optimally damped running gear, which also absorbs large shock loads. In this respect, the substantial support wheel not only ensures precise depth control but also provides optimum soil compaction protection. In addition, the standard hydro-pneumatic suspension of the support wheel ensures maximum driving comfort and safety on the road.

The Tyrok headstock, which can rotate through 180°, ensures an optimum pull line with the minimal lateral pull, and thus reduced pull force requirement. In addition, it also provides outstanding flexibility for attachment as a result of its various coupling alternatives. The Tyrok can also be optionally equipped with traction control for reduced slippage. In this case, another hydraulic cylinder transfers weight to the rear axle of the tractor. This provides maximum pulling power and fuel savings.

All hydraulic functions can be conveniently accessed with very little effort from the front of the headstock in the central SmartCenter settings centre.

Completely equipped for complete performance

Optional soil engaging tools allow the new semi-mounted reversible plough to be universally adapted to all operating conditions. For example, various skimmers or trash boards are available for the clean incorporation of large amounts of organic matter. Additional landside protectors can be attached to the shares to ensure better plough guidance on slopes.

An optional sword landside, which protects the edges of the front shin of the mouldboard from wear and cuts a clean furrow wall, is ideal for regions with stony and heavy soils. Disc coulters can be fitted to the last body for an exceptionally clean furrow clearance.

For simultaneous reconsolidation, AMAZONE offers the Tyrok 400 with a swivel press arm for working with a packer.

The advantages at a glance:

- Efficient, easily-adjustable and robust semi-mounted reversible plough with high operational reliability

- Durable and sturdy SpeedBlade plough body for higher working speeds – as a result of the extended front shin of the mouldboard and ©plus hardening process

- Precise working depth over the entire length of the plough, thanks to the large rectangular tubular frame

- Perfect matching of the ploughing, even under varying conditions, thanks to the standard hydraulic front furrow adjustment

- Automatic adaption of the front furrow to the overall working width by means of AutoAdapt

- Rapid and gentle turnover process as a result of the hydraulic end position damping – SmartTurn

- The substantial support wheel ensures an exact depth control and the optimum soil structure protection

- Maximum safety and comfort in the transport position due to the standard wheel shock-absorber

- Shear bolt or hydraulic overload safety protection for a positive re-entry into the soil

- Comfortable and central SmartCenter settings centre on the plough headstock