Innovation from tradition - 75 years of AMAZONE seed drills

The development of AMAZONE seed drills

Precise seed drills for ploughing, mulch and direct seeding from AMAZONE, the combination world champion!

AMAZONE developed the first D1 drill in 1949. When, in 1966, AMAZONE first launched its combination of reciprocating harrow and D4 seed drill, it was a completely new technique and it also represented the beginning of a long story of success. This innovation was a huge step forward for farmers. This was because the combination of active soil tillage and sowing made it possible to reduce the number of passes and achieve even field emergence.

We are the combination world champions! We can make this claim because we find this integrated system of seedbed preparation, reconsolidation, seed placement and seed embedding has been adopted on farms all over the world. In addition to the conventional and pneumatic mounted and harrow-mounted seed drills, the AMAZONE range also includes other additional models. These include the Cirrus trailed seed drill combination, the Primera DMC tine seed drill and solo seed drills, such as the Citan with a working width of up to 15 m. No other agricultural machinery manufacturer can offer its customers such a comprehensive range of seed drills and seed drill combinations as AMAZONE.

AMAZONE seed drills - an extraordinary story of success

The origins of the seed drill go back to 1949. At that time, Dipl. Eng. Heinrich Dreyer, the son of the company founder, together with Mr Kademann, developed the first D1 seed drill with a working width of 2 m, which was equipped with the innovative Elite seed wheel for fine and normal sowing. This seed drill revolutionised the drilling of multiple seed types because, unlike the seed drills of that time, the D1 did not require the seed wheels to be constantly changed.

1966 saw an active seed drill combination launched onto the market for the first time ever in the form of the legendary D4 seed drill combined with a RE reciprocating harrow. The D4 was so popular that, just four years later, AMAZONE was producing around 4,000 units a year, making it by far the market leader in Germany. Initially, the D4 was only offered as a 3 m version, but later on in working widths from 2.5 m to 4 m - and even up to 8 m with a coupling frame. Its successor model, the D7, introduced in 1972, became one of the world's best-selling seed drills.

When the RPD DrillStar tyre-packer sowing combination was launched in 1988, AMAZONE offered the first tyre packer roller as an alternative to either a cage roller or tooth packer roller. The tyre packer roller offered targeted reconsolidation just to the seed row, which was further optimised with the invention of the wedge ring roller in 1998.

From the drawing board and slide rule to the screen and software

Then as now, the goal of the AMAZONE designers has remained the same: Developing and realising innovative ideas that enable customers to work ever more precisely, flexibly and effectively.

The latest development in conventional , gravity seed drill combinations is the Cataya, which features a precise metering system, electric drive of the seed shaft and a central settings centre for quick adjustment and calibration of the metering system.

In addition to the range of conventional seed drills, pneumatic drills were added to the product range in 1995. The foundation was laid with a pneumatic front packer seed hopper in combination with a rotary cultivator and a tyre packer seed rail. An up-to-date version of the Airstar Avant seed drill combination with mounted front hopper is still available today in working widths up to 6 m. This was followed by continual developments, such as the renowned Airstar AD-P pneumatic harrow-mounted seed drill, and further optimisations which have lead to today's Centaya. The Centaya has an electrically driven seed metering unit and can be equipped either with TwinTeC double disc coulters or the RoTeC pro single disc coulter as an option.

To meet the demand for higher output seed drill combinations in conjunction with passive soil tillage implements, the Cirrus pneumatic large-area seed drill, which features passive soil working tools and comes in working widths of 3 m to 6 m, was introduced in 2001. The flagship of this product range is the recently launched Cirrus Grand with its impressive 9 m working width.

Dr. Heinz Dreyer managed to achieve another milestone with the introduction of the NT direct seed drill and its successor, the Primera DMC for direct seeding, mulch sowing and conventional seeding in the large-area seeding technology segment. The invention of the chisel opener made it possible from then on to carry out direct seeding on unworked soils. In addition to the Primera DMC, the range of tine drills has been extended in the last decade by the introduction of the Cayena and Condor seed drills. Due to their special sowing coulters, and large working widths of up to 15 m, both seed drills can be used to achieve high outputs on an extremely wide variety of soils.

This product portfolio allows AMAZONE to offer its customers a wide variety of seed drills and sowing methods in working widths ranging from 2.5 m to 15 m.

Quote from Dr. Heinz Dreyer (1932 – 2023)

Our French representative arrived and said we had to build a new seed drill, something completely new. So I went back to my drawing board and developed various seed drills - until he said, "That's it. That’s what we made. That was the D4 - the legendary D4. We then went from a few hundred to a few thousand per year within a short period of time and became the market leader.

It is probably every designer's dream to develop a machine that is so good that the entire competition feels compelled to copy it over the years.

From the drawing board and slide rule to the screen and software

Then as now, the goal of the AMAZONE designers has remained the same: Developing and realising innovative ideas that enable customers to work ever more precisely, flexibly and effectively.

Milestones in 75 years of AMAZONE seed drills!

1949:

First AMAZONE D1 seed drill

1964:

First modern tractor mounted drill AMAZONE D4

1966:

First modern D4 drill combination with RE reciprocating harrow

1972:

Classic mounted seed drill

AMAZONE D7

1975:

AMAZONE NT direct seed drill for No Till

1978:

The first KG rotary cultivator with “on-grip” tines

1980:

First AMAZONE roll disc coulters

1985:

KE rotary harrow

1987:

Primera DMC direct seeder for direct, mulch and conventional sowing

1988:

AD harrow-mounted conventional seed drill

1988:

Tyre packer drill combination RPD DrillStar

1993:

Seed drill combination with mounted front hopper

Airstar Avant

1993:

RP-AD DrillStar tyre packer mounted combination

1995:

Pneumatic seed drill

Airstar AD-P

1998:

Pneumatic trailed seed drill Airstar XACT

1999:

D9 mounted conventional seed drill

2003:

Cirrus trailed cultivator drill

2005:

Citan large area solo seed drill with a working width up to 15 m

2009:

Condor tine coulter seed drill up to 15 m working width

2009:

Cayena tine coulter seed drill

2016:

Cataya conventional drill combination

2016:

Centaya pneumatic harrow-mounted seed drill

2018:

CombiDisc compact mounted disc harrow with the Centaya harrow-mounted seed drill

2023:

Cirrus Grand trailed seed drill combination with a 9 m working width

flexible –water-conserving – precise

On farm, the seed drill plays a key role in all arable farming systems. Perfect sowing forms the basis for maximum yields.

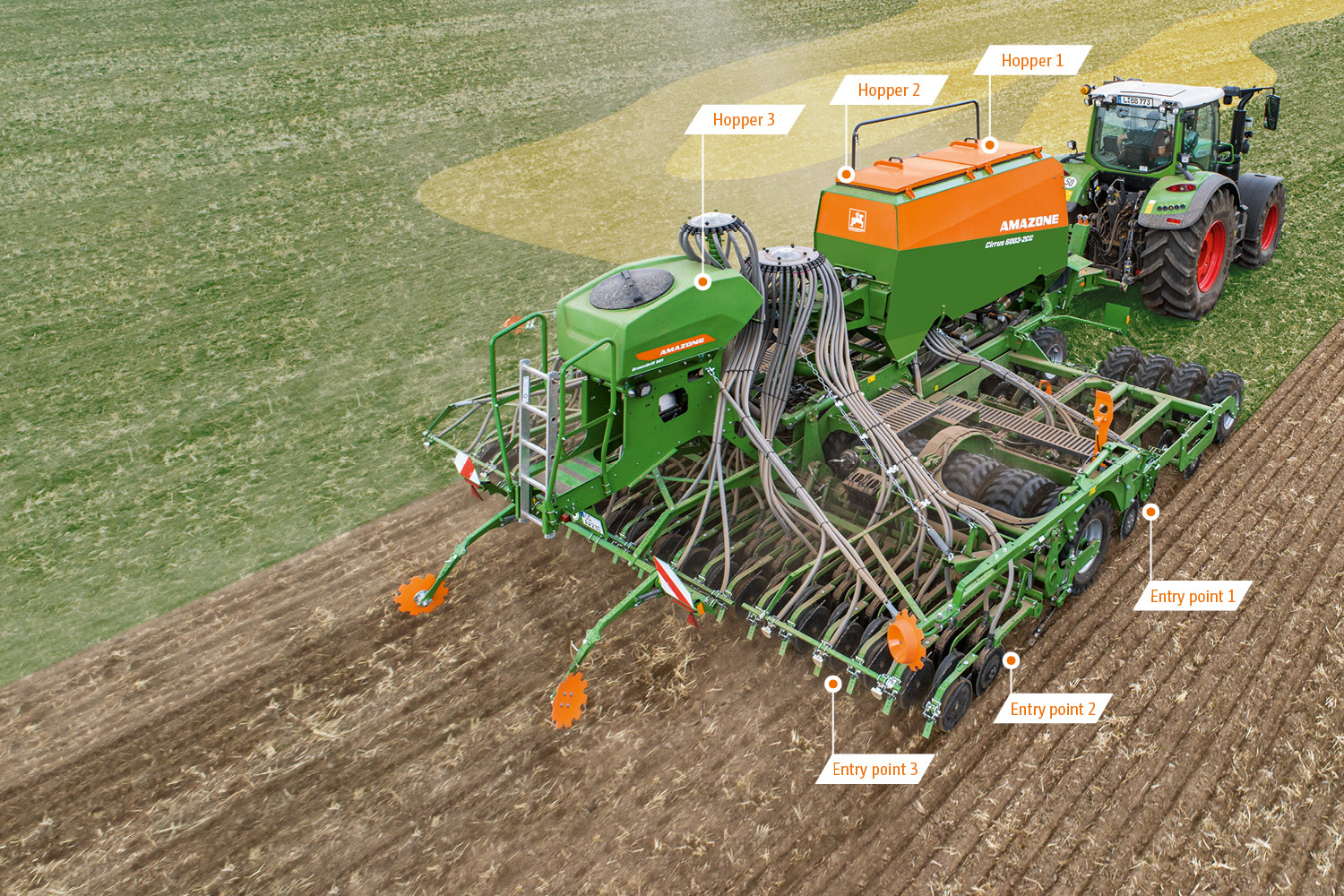

The trailed Cirrus universal seeding combination comes into its own, not only after the plough and when mulch sowing, but also in water-conserving minimum-till sowing in strips or without any prior seedbed preparation. The application of up to 3 different materials at up to 3 delivery points in the triple-shoot process can also be implemented to perfection with the Cirrus. The Cirrus offers the option of spreading fertiliser as well as seed at various delivery points in a single pass. In addition to this, the seed rates of the individual products can be tailored on a part-area, site-specific basis by means of application maps.

See for yourself!

All the methods at a glance

Single-Shoot

- Via the sowing coulter

- Support of the plant at the early growth stages

- No leaching or evaporation of the fertiliser

Double-Shoot

- Via the sowing coulter + fertiliser coulter or GreenDrill, e.g. via baffle plates

- Deep deposition of fertilisation extends the availability of the fertiliser

- Fertiliser can be placed between the rows

- Improved root development thanks to the initial dosage of the fertiliser

Triple-shoot

- Via the sowing coulter + fertiliser coulter + GreenDrill, e.g. via baffle plates

- Companion plants sown on the surface suppress weeds

A wide variety of agronomic methods are easy to implement with the Cirrus

AmaTron 4 ISOBUS terminal – Comfortable operation as intuitive as your tablet

The 8" low-reflection multi-touch colour display allows easy reading and quick input of all the necessary information. The AmaTron 4 ISOBUS terminal is universally usable for all ISOBUS machines from AMAZONE and also machinery from other manufacturers.